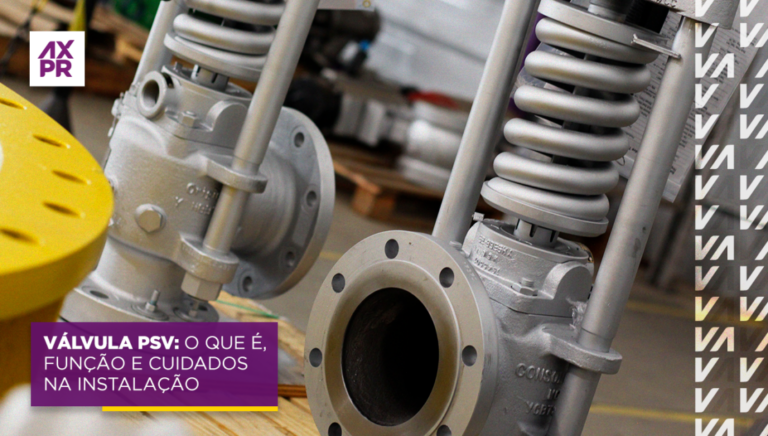

This article is the first part of a special series on safety relief valves, where Artur Cardozo Mathias, an expert on the subject, explains more about some characteristics of this category of valves.

Today, the discussion is about the storage, transportation, and installation of safety relief valves. Stay tuned for upcoming articles, where we will delve into the details of the design of the inlet pipeline and also the design and installation of the discharge pipeline for these valves.

-

Both the incorrect operation of a safety relief valve (even when well-designed, specified, and sized) and operational problems encountered during its operational cycle (opening, overpressure, and closing) are directly related to less careful storage, transportation, and handling during installation.

In addition to the factors mentioned above, incorrectly designed installations, both for the inlet and discharge pipelines, also contribute to this.

After all, careful storage, transportation, and handling during installation would be of no avail if the installation was not correctly designed. Similarly, having a correctly designed installation would be of no use if due care was not taken during storage, transportation, and handling during installation.

Safety relief valves should always be stored upright in a safe and dust-free environment when awaiting installation, and, if possible, inside their original packaging.

The entry of foreign materials into the valve nozzle (or between the guide components) can compromise the sealing and operation of the valve. The same care should also be taken regarding the outlet nozzle of the vessel or boiler for the valve's entry, as there is typically no flow in this nozzle while the valve is closed.

Balanced safety relief valves with bellows should always operate with the bonnet exposed to atmospheric pressure through the relief hole in the bonnet. Therefore, this relief hole should also be protected until the moment of installation, and this protection should be removed from the moment the valve is put into operation.

The storage of valves with resilient seats should be in environments with temperatures between -10°C and 40°C. When the valve has metal seats, the ambient temperature should be between 5°C and 40°C.

Every safety relief valve should be transported to the installation site, preferably, just before installation. The flange protectors should only be removed when assembling the valve on the equipment to be protected.

If there is any doubt regarding the care taken during storage, handling, or transportation of the valve (or even for valves that have been carefully stored for several months), it is recommended to perform a bench test to measure the set pressure and sealing of the valve before transporting it to the installation site.

During the transportation of the safety relief valve from the workshop to the installation or during the transportation from the installation to the workshop (in the latter case, whenever it has to undergo "reception testing"), care in handling during its disassembly from the protected equipment—and during transportation to the test bench in the workshop—should also be careful and always in the upright position.

Misalignment of Internal Components

This can be considered the main consequence of less careful storage and transportation of a safety relief valve, especially when transported horizontally.

The consequences of misalignment of internal components are:

- Leaks through sealing surfaces at the operating pressure;

- Inconsistent operation;

- Changes in the opening pressure value;

- Higher relief differential value (closing pressure further away from the set pressure and very close, and sometimes even colliding, with the operating pressure).

Therefore, it is important to remember: correct alignment of internal components allows for maintaining sealing, as well as the repeatability of the valve's opening pressure for a long period.

Therefore, it is important to remember: correct alignment of internal components allows for maintaining sealing, as well as the repeatability of the valve's opening pressure for a long period.

Therefore, every safety relief valve should be treated as a precision instrument because it is the last line of protection for lives and properties within an industrial process. This protection depends on correct installation to ensure a perfect operational cycle.

See you in the next article, where we will talk more about safety relief valves, specifically about details of the design of the inlet pipeline. Until then!