Safety valves (PSV) and relief valves (PRV) have specific engineering and characteristics.

Understanding the properties of each allows you to save time and money by knowing when and where to use them. Want to know how? We'll explain below.

In this article, you will learn the difference between PSV and PRV valves and identify:

- Definition of safety and relief valves.

- How the PSV equipment works.

- How the PRV equipment works.

- Curiosities about PSV and PRV.

PSV or PRV?

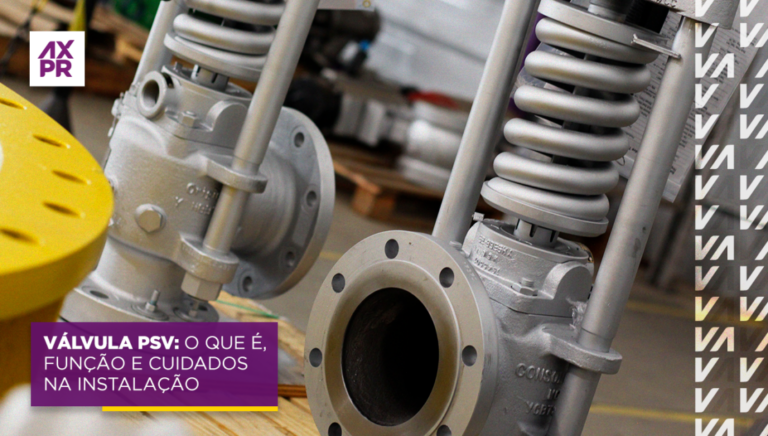

The safety valve, also known as PSV, Pressure Safety Valve, is an automatic pressure-limiting device characterized by instant opening, known as "POP," which occurs when the process pressure reaches the defined opening pressure for valve actuation.

On the other hand, the relief valve, known as PRVPressure Relief Valve, is an automatic pressure-limiting device but characterized by a gradual and proportional opening to the overpressure.

So, which one should I choose for my application? The choice between PRV and PSV depends on the fluid flowing in the pipeline where the valve will be installed: (i) if the fluid is incompressible, PRV is typically used, as in water or oil relief applications, while (ii) PSV is used for the discharge of compressible fluids, such as water vapor or natural gas.

Understand how PSV works

Reservoirs, boilers, tanks, reactors, and pipelines are all equipment designed to withstand specific working conditions, depending on fluid, pressure, and temperature, and therefore have known limitations. If the design pressure is exceeded due to scenarios like fire, control valve failure, impact, or even operational errors, the equipment can bulge, collapse, rupture, or even explode, leading to severe environmental, asset, and life damage. This was the tragic fate of various boilers and steam engines at the beginning of the first industrial revolution, but thanks to a good inventor, the creator of safety valves, these episodes no longer happen as before.

But what is the operating principle of these valves? Simple as a tug of war.

The fluid pushes from one side, and a device pushes from the other. If the fluid is stronger, the device allows passage, relieving pressure. Let's give you an example to better understand how PSV works.

Firstly, it is essential to know what a set point and blowdown are. The set point is the opening pressure, i.e., the gauge pressure at which the valve is set to open when requested. Blowdown is the relief differential, that is, the difference between the opening pressure and the closing pressure (on return) of the valve.

Let's go to the example: a safety valve in a vessel operating at a pressure of 60 bar. The total opening pressure (set point) is set at 80 bars. When the line pressure (which normally operates at 60) is exceeded and reaches the set point, the valve opens automatically, or for insiders, it gives a POP. As the fluid escapes to a reservoir or the atmosphere, the line pressure begins to decrease until it reaches a safe pressure level where the valve automatically closes. The ratio between the set point and the pressure at which the valve closes is the definition of blowdown.

Therefore, remember: In safety valves or PSV, the set point and blowdown can be adjusted.

Understand how PRV works

Following the same example we presented earlier, unlike PSV, PRV will not open completely at the set point pressure but proportionally to the overpressure from the set point. Just like in the opening, the closure will also be proportional to the overpressure, and therefore, they do not have a standardized or adjustable parameter for blowdown.

Interesting, isn't it?

Curiosities about safety valves (PSV) and relief valves (PRV)

Here are some curiosities about safety valves (PSV) and relief valves (PRV):

- You cannot use the relief valve in a steam line, never! The safety valve can be used in a water line, but it is unnecessary because it has a higher cost and becomes inefficient.

- The PSV is the last line of defense against an accident. And it cannot fail!

- The basic information for sizing PRV and PSV includes: operating pressure, opening pressure, required discharge flow, operating temperature, vessel-tank standards, and fluid characteristics.

- For the relief valve, the flow unit is in volume per time (used for liquids and gases). In the safety valve, the flow is given in mass per time since it is specifically used for gases or vapors.

- In maintenance, it is possible to convert a safety valve into a relief valve and vice versa by replacing internal elements. And it is very worthwhile because the cost is lower than acquiring a new valve.

- The American Society of Mechanical Engineers (ASME), in 1915, developed standards for the design, sizing, inspection, and installation of safety valves. These standards are known, revised, and applied to this day. Two of these standards govern PSV: ASME I defines design requirements for boilers. ASME VIII defines design requirements for pressure vessels and pipelines.

- The allowed blowdown range for PSVs is defined by ASME I and ASME VIII, the former between 2 and 4%, and the latter, up to 7%.

- In Brazil, IBP's Guide 10 is an excellent resource to learn more about PSV maintenance and widely used as a reference in calibration procedures.